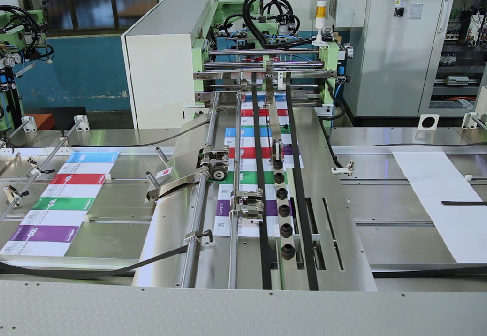

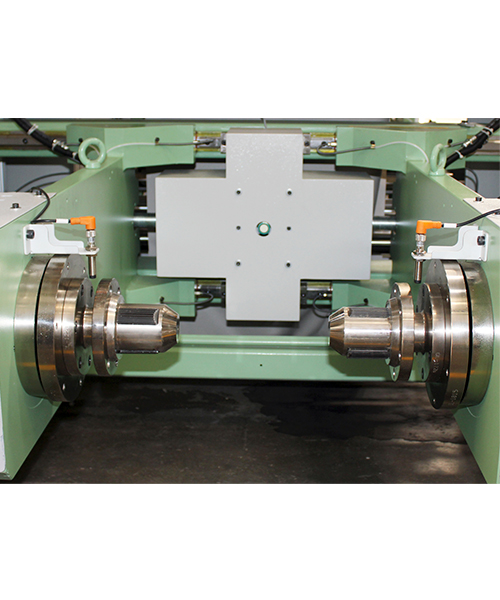

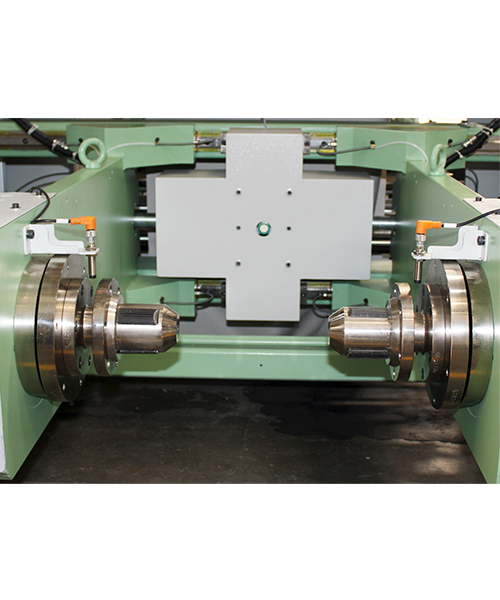

Bunch Gathering Unit

Precise Counting with Uniform Stacking

Punching Unit

Sturdy Design with Multi Type Hole Punch Facility

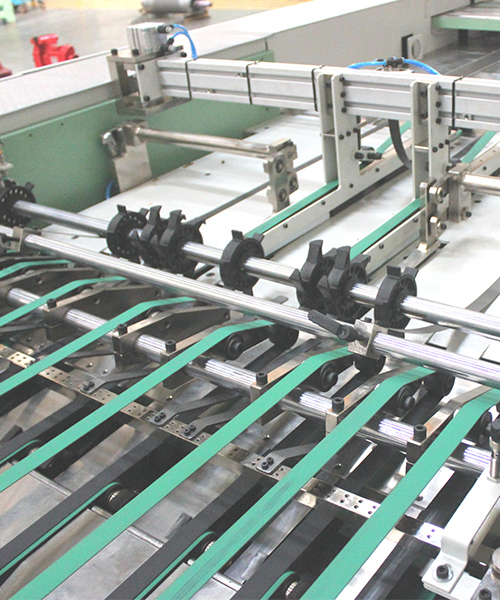

Sheet form Inserter

Smooth insertion of covers

Control Panel

HMI/PLC with Online Connectivity

Separating & Cutting Unit

Heavy & Robust Design for Accurate Cutting

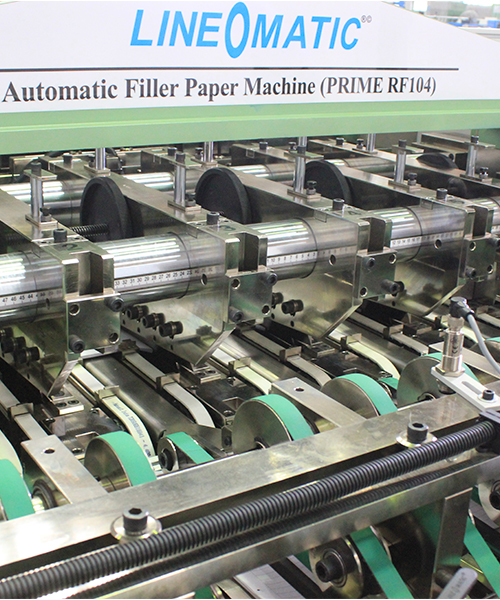

Paper Counting Unit

Counting Without Changing Gears

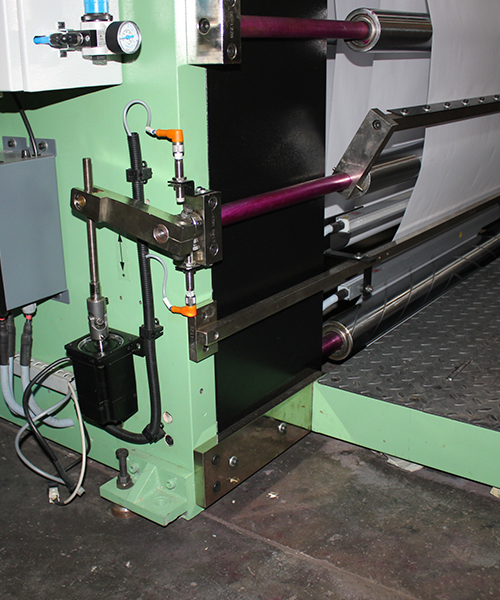

Printing Unit

One-piece Robust Structure With Self-aligned Bearings

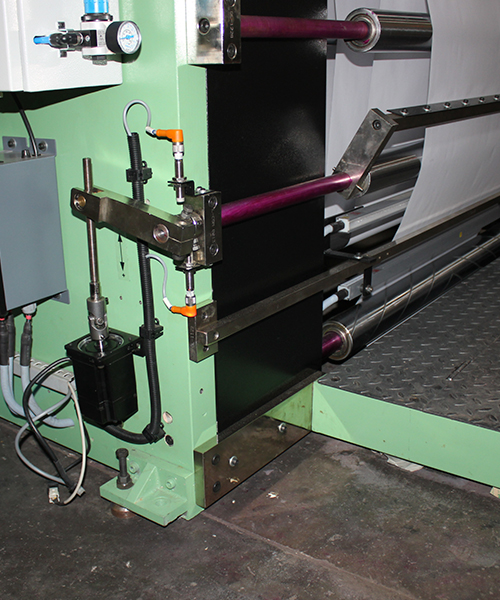

Reel Unwind Stand

Shaftless Lifting

-

Speed* 300 Meters/Minute

Speed* 300 Meters/Minute -

Converting Strokes* 40 Cycles/Minute

Converting Strokes* 40 Cycles/Minute -

Max. Ups 6 Maximum

Max. Ups 6 Maximum -

Automatic Filler Paper Machine

- Prime RF120

The Prime RF120 consists of the following components: a reel unwinding stand, two-color printing towers, a micro perforating unit, a cross-cutting unit, a sheet overlapping unit, a sheet counting and collating unit, an inserter for pre-printed title covers, a hole punching unit, a partition cutting unit, a bunch gathering unit, a straight conveyor, and a centralized control panel (PLC).

Filler Paper Manufacturers Needing

- High output

- High-quality end products

- High level of automation

- Low production cost

- Minimum manpower

- Consistent performance

- Excellent quality output

- Longer life

- Easy to operate & very low maintenance

Auto Splicer

- Splicing speed - 90 m/min

- Strokes - 50 cycles/min

- Strokes - 80 cycles/min

- Strokes - 25 cycles/min

Technical Specification

| Model | Prime RF120 |

|---|---|

| Web Speed* (meters/minute) | 300 |

| Converting Stroke* (cycles/minute) | 40 |

| Number of Ups (max.) | 6 |

| Reel Width (mm) | 600 to 1200 |

| Printing Width (mm) | 600 to 1190 |

| Reel Diameter (mm) | 1400 |

| Core I.D. (mm) | 76.2 |

| Reel Weight (Kgs.) | 1700 |

| Printing Tower | 2 color flexo units on each side |

| Printing Length (mm) | 340 to 680 (variation of 2.5 mm) |

| Cutting Length (mm) | 210 to 340 (variation of 2.5 mm) |

| Sheet Count | 6 to 30 |

| Paper (GSM) | 45 to 70 |

| Index & Title (GSM) | 50 to 400 |

| Max. Punching Thickness Capacity* (mm) | 2.5 (2000 GSM) |

| Rec. Floor Space (L x W x H) (meters) | 22 X 13 X 4 |

| * Machine Speed and Converting Strokes will depend on bunch sheet count, cut size and GSM of the paper being used. | |

Request a Quote

Request a Quote

Download Brochure

Download Brochure