Being a leader comes with many prerequisites. One of the most important is being fully equipped with the latest avant-garde technologies.

To comply with this, Lineomatic has established a state-of-the-art production facility spread over 350,000 square feet in Ahmedabad, Gujarat.

But that is not all for the company. Backward integration is also a term that leads to complete quality control, and the company makes sure that everything, from the parts of the machine to the final product, is produced in-house, complying with international standards.

Solar Power

For the first time in Ahmedabad, we are equipped with a 200 KW Solar Power Generation Plant, which will help us become self-dependent when it comes to electricity requirements.

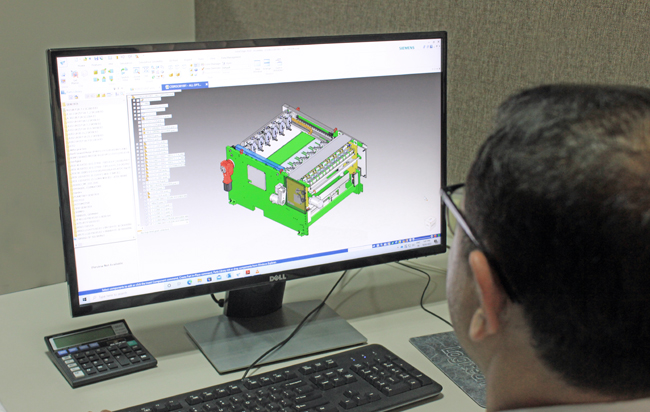

Thus, Lineomatic has also established ultra-modern manufacturing set-ups with new machines from leading countries for the best quality production. It also possesses various types of CNC machines in-house. All units have established and applied a stringent quality control system for the design, development, and production of paper-converting machinery according to the requirements of ISO 9001:2015.

More than 90% of parts are manufactured in-house with the best metallurgy and are under stringent quality control—an under-modern manufacturing setup.

The company's design department works incessantly to keep pace with technological advancements in the world and designs the most futuristic machines. At the same time, an expert and dedicated workforce of more than 700+ skilled professionals assures the finest quality products and faster delivery of goods.

Unit 1

At here, We have our office set-up, management, production, store & quality control

Unit 2

At here, We manufacture machine spares and components

Unit 3

At here, We manufacture large components, walls structures and rollers

Unit 4

At here, We manufacture fabrication components of our Lineomatic machines.